What if a small change to your machinery could cut energy costs by 15% and shrink your carbon footprint? Industries worldwide grapple with rising expenses and environmental demands. Energy-efficient industrial belts offer a practical fix. These belts, including industrial drive belts, reduce power waste while supporting sustainability goals. Imagine a warehouse or factory running smoothly, consuming less energy, and emitting fewer greenhouse gases—all thanks to smarter belt designs. This blog dives deep into how industrial belts can revolutionize operations. We will cover innovative designs, eco-friendly materials, key providers, and maintenance strategies.

The Case for Energy-Efficient Industrial Belts

Industrial belts are the backbone of countless machines. When optimized for efficiency, they save energy, lower costs, and ease environmental strain. This is critical as industries face growing pressure to go green.

How Belts Affect Energy and Emissions

Inefficient belts drag down performance. They force motors to overcompensate, burning extra fuel and releasing more CO2. Energy-efficient industrial belts flip that dynamic.

- Reduced Friction: Smoother surfaces cut resistance.

- Balanced Tension: Proper fit avoids excess strain.

- Longevity: Durable builds reduce replacement frequency.

Tangible Benefits for Businesses

Switching to efficient industrial drive belts delivers more than eco-points. It is a practical choice.

- Lower Expenses: Less energy use trims bills.

- Reliable Output: Machines run without stutters.

- Regulatory Fit: Meets green standards effortlessly.

A Broader Impact

These belts align with global sustainability targets. They help industries cut emissions without sacrificing productivity. It is a small tweak with big ripple effects.

Cutting-Edge Belt Designs for Efficiency

Not all industrial belts are created equal. Some excel at minimizing energy loss, making them stars in the push for sustainability. Let’s explore the top designs.

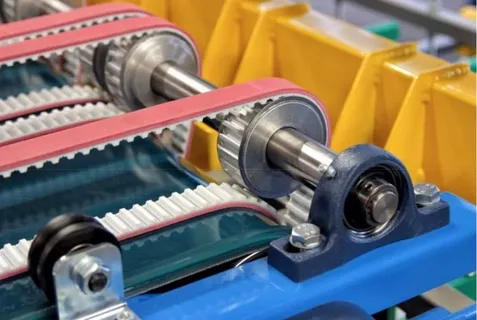

Synchronous Belts for Precision Power

Synchronous belts, also called timing belts, lock into pulleys with no slippage. They are a standout among industrial drive belts.

- Toothed Design: Grips firmly, saving energy.

- Lightweight Build: Less mass means less power needed.

- Applications: Conveyors, pumps, and belt automotive systems.

Low-Friction Rubber Conveyor Belts

Rubber conveyor belts with low-friction coatings move goods effortlessly. They are built for tough jobs.

- Special Coatings: Reduce drag over long distances.

- Heat Resistance: Performs in harsh conditions.

- Uses: Mining, shipping, and food processing.

High-Efficiency V-Belts

V-belts are classics in power transmission belts. Modern upgrades make them greener.

- Slim Profiles: Less material, more efficiency.

- Flexible Cords: Bend without losing power.

- Durability: Fewer replacements, less waste.

Flat Belts for Simplicity

Flat belts offer a straightforward, efficient option for specific setups.

- Even Load: Distributes force smoothly.

- Low Stretch: Maintains steady energy use.

- Niche Fit: Small machines or light-duty tasks.

Modular Belts for Flexibility

Modular belts, made of interlocking pieces, adapt to complex systems.

- Custom Fit: Adjusts to unique layouts.

- Easy Repair: Swap parts, not the whole belt.

- Efficiency: Reduces downtime and waste.

Materials That Power Sustainability

The materials in industrial belts define their performance and eco-impact. Innovations here cut energy use and waste, boosting green efforts.

Synthetic Fibers in Power Transmission

Industrial drive belts often use synthetic fibers like aramid or polyester. They are tough yet light.

- High Strength: Handles heavy loads.

- Low Weight: Needs less energy to move.

- Wear Resistance: Lasts through tough cycles.

Eco-Friendly Industrial Leather Belts

Leather belts, when sustainably sourced, bring a natural edge.

- Renewable Roots: Cuts synthetic dependency.

- Stable Shape: Minimal stretch keeps efficiency high.

- Best Use: Smaller, precision-driven systems.

Recycled Materials in Conveyor Belts

Industrial conveyor belts made from recycled rubber or plastics are gaining traction.

- Waste Reduction: Reuses discarded materials.

- Solid Performance: Matches new belts in strength.

- Green Story: Highlights eco-commitment.

Advanced Coatings for Less Friction

Coatings like silicone or Teflon make belts slicker and tougher.

- Smooth Run: Lowers resistance.

- Tough Layer: Resists heat and wear.

- Long Life: Extends usability.

Bio-Based Options Emerging

Some belts now use bio-based materials like plant-derived polymers.

- Eco-Source: Reduces fossil fuel use.

- Light Build: Cuts energy demands.

- Future Fit: Early adopter appeal.

Providers Shaping the Industry

Companies like Saudi V-Belt Industries, General Industries Co. Ltd, and Bearing World deliver industrial belts that meet sustainability needs. Each offers distinct advantages.

Saudi V-Belt Industries’ Local Expertise

Saudi V-Belt Industries (SBI) produces industrial belts in the Kingdom. Their V-belts excel in power transmission, built with local know-how.

General Industries’ Rugged Solutions

General Industries Co. Ltd specializes in durable industrial belts. Their rubber conveyor belts tackle heavy industries like mining with ease.

Bearing World’s Comprehensive Offerings

Bearing World stocks a wide range of industrial drive belts. Their focus on technical support and fast delivery keeps clients running efficiently.

The belt market offers variety. SBI shines with locally made V-belts, perfect for power needs. General Industries brings heavy-duty conveyor expertise to the table. Bearing World, however, covers more bases—offering everything from timing belts to industrial conveyor belts. Their quick shipping, hands-on training, and proactive maintenance programs help clients avoid energy-wasting issues. It is a practical advantage for businesses aiming to stay lean and green.

Why Choice Matters

Picking the right provider isn’t just about products. It is about support, availability, and alignment with your goals. The best fit depends on your industry and priorities.

Maintenance Strategies for Peak Performance

Even top-tier industrial belts need care. Smart maintenance keeps them energy-efficient and eco-friendly, maximizing their impact.

Regular Tension Checks

A belt too loose or tight wastes energy. Stay proactive.

- Tools: Use a tension gauge for precision.

- Timing: Check monthly to catch drift.

- Result: Steady power, no excess draw.

Clean and Lubricate Properly

Dirt and grime sap efficiency from industrial drive belts. Keep them in top shape.

- Wipe Down: Remove dust and debris.

- Light Lube: Apply belt-safe products sparingly.

- Benefit: Smoother runs, lower costs.

Monitor Wear Patterns

Worn belts lose efficiency fast. Spot issues early.

- Visual Scans: Check for cracks or fraying.

- Timely Swap: Replace before failure hits.

- Payoff: Consistent output, less waste.

Align Pulleys Correctly

Misaligned pulleys strain belts and waste power. Fix it.

- Inspect: Check pulley angles regularly.

- Adjust: Keep them aligned.

- Gain: Less wear, more savings.

Temperature Control

Heat can degrade belts. Manage it well.

- Ventilation: Ensure airflow around belts.

- Monitor: Watch for overheating signs.

- Outcome: Longer life, steady efficiency.

Conclusion

Energy-efficient industrial belts are a game-changer for modern operations. Designs like synchronous belts, low-friction rubber conveyor belts, high-efficiency V-belts, and modular systems cut energy loss while advancing sustainability goals. Materials—synthetic fibers, recycled rubber, eco-leather, and bio-based options—amplify the effect, reducing waste and emissions. Providers like Saudi V-Belt Industries, General Industries, and Bearing World bring these solutions to life, offering belts tailored to diverse needs. Maintenance locks in the benefits: check tension, clean regularly, monitor wear, align pulleys, and control heat to keep belts performing. These steps save money, boost reliability, and shrink carbon footprints. Ready to make your operation greener and more efficient? Visit www.bearingworld.com.sa to explore Bearing World’s extensive range of industrial belts and expert support—your next move toward a sustainable future starts there.