Engineers often look for workbench systems that can change just as quickly as their testing requirements. A setup that’s sturdy one week may need new fixtures, sensors, or layout adjustments the next. MiniTec Aluminum Framing offers that kind of adaptability, which is why it has become a preferred choice for modern test bench designs across labs, production floors, and research environments.

Lightweight Profiles Make Repositioning Benches Easy

MiniTec extruded aluminum framing is known for its lightweight structure, which allows teams to reposition benches without specialized equipment. This makes it easier to redesign testing zones, shift benches between work areas, or integrate new tools as projects evolve. The reduced weight doesn’t compromise stability—an important balance for teams working in dynamic environments. The lighter profile also reduces fatigue for technicians who frequently adjust their layouts. With extruded aluminum T slot systems, even large assemblies can be moved or lifted with minimal strain. MiniTec Solutions supplies framing that supports smooth workflow changes without overwhelming the user with heavy-duty adjustments.

Strong Modular Slots for Flexible Fixture Mounting

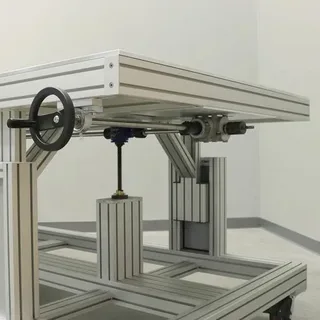

The T slot extrusion system provides a built-in modular mounting solution. These slots allow fixtures, clamps, instruments, and sensors to be placed exactly where needed—without drilling or welding. That flexibility is essential for test benches that must adapt to various prototypes, measurement devices, or inspection tools.

A major advantage is the level of precision and repeatability this system provides. Components can slide, lock, and reposition with ease, making it simple to reconfigure test setups multiple times a day. MiniTec Aluminum Framing supports countless mounting options, letting users build customized setups on demand.

Corrosion Resistance Ideal for Lab and Workshop Setups

Testing environments often include moisture, oils, coolants, or chemicals that can degrade certain materials. MiniTec extruded aluminum framing offers natural corrosion resistance, which keeps test benches looking clean and performing reliably over time. This makes it a preferred choice for labs that demand hygienic surfaces and workshops exposed to harsh materials.

The corrosion-resistant nature of T slot aluminum extrusion also reduces long-term maintenance. Users do not need constant repainting, sealing, or rust prevention treatments. MiniTec Solutions delivers framing that withstands daily wear without losing structural integrity.

Simple Cut and Join Methods Speed Assembly Time

Test bench systems built from MiniTec Aluminum Framing can be assembled rapidly thanks to simple cutting and joining methods. Profiles are easily cut to length and connected with standardized hardware, removing the need for welding or advanced fabrication tools. This shortens project timelines and allows teams to build benches as soon as parts arrive.

The simplicity of assembly also supports error-free construction. Teams can test, adjust, and rebuild sections without starting from scratch. MiniTec extruded aluminum framing streamlines build processes while supporting high precision in the finished structure.

Reusable Components Help Adapt Benches As Needs Change

One of the most practical advantages of T slot extrusion lies in reusability. If a test bench needs to change size, height, or function, components can be disconnected and reused in new configurations. This makes MiniTec Aluminum Framing a cost-effective long-term investment for facilities with rotating project demands. Reuse also reduces waste. Instead of fabricating new steel benches or discarding welded frames, teams can recycle existing components into new structures. MiniTec Solutions supports sustainable workflows by offering systems built for long service life and repeated redesign.

Compatible Accessories Expand Tooling and Storage Options

Versatility expands further with MiniTec’s accessory ecosystem. Shelving, drawers, monitor arms, cable guides, lighting mounts, and tool holders can easily attach to the T slot extrusion. These accessories help workers organize tools, route wiring, or position instruments exactly where needed during testing.

This compatibility eliminates the headache of finding parts that fit. Because accessories attach directly to the framing, users avoid custom machining or bracket fabrication. MiniTec extruded aluminum framing systems create a unified, modular test bench environment.

Rigid Framing Supports Heavy Test Equipment Securely

Although lightweight, T slot aluminum extrusion is engineered for strength. MiniTec Aluminum Framing can support heavy equipment such as torque testers, load cells, pneumatics, precision measurement devices, and multi-axis sensors. Its internal geometry distributes weight evenly, maintaining rigidity under demanding loads.

The strength comes not just from the material, but from the design of the profile and connectors. Test equipment must stay stable to ensure accurate readings, and MiniTec’s extruded aluminum T slot structure provides that reliable stability. MiniTec Solutions helps teams configure frames that withstand industrial-grade testing requirements.

Pre-drilled Grooves Reduce Custom Fabrication Needs

Pre-drilled grooves make it easy to run wiring, mount switches, or attach protective panels without additional machining. These grooves also enable fast installation of fasteners and connectors, cutting down on modification time. This reduces labor hours and eliminates many fabrication steps required with traditional steel frames.

Because wiring and tubing can run through these grooves, test benches stay clean and organized. Hidden cabling improves safety and reduces interference with equipment. MiniTec extruded aluminum framing brings built-in functionality that shortens setup time.

Clean Industrial Look Blends Well with Professional Spaces

A test bench often reflects the professionalism of the workspace. MiniTec Aluminum Framing offers a clean, modern appearance that fits well in labs, engineering offices, and production environments. The brushed aluminum finish creates an organized, intentional look—something clients and team members notice when visiting a testing facility.

This visual appeal also helps teams maintain pride in their workspace. A tidy, well-designed bench encourages proper organization and consistent workflow. MiniTec Solutions delivers framing that performs well and complements the overall aesthetic of a professional testing environment.

MiniTec Solutions supports test bench applications by supplying reliable extruded aluminum T slot systems, accessories, and custom configurations that help engineering teams build flexible, durable, and efficient workstations tailored to changing project demands.